Tom Luedecke is Under Armour’s VP of Footwear Development and Engineering. He and his basketball sneakers have been around the block a few times. His name, to keep it as simple as possible, is attached to some famed silhouettes. And even after everything he’s done in the industry, he’s speaking with the excitement of a fresh-out-the-blocks rookie about Curry Brand while he takes a walk down memory lane in a pair of Curry 8s.

“November 2019, we met up with [Stephen Curry] near Stanford at a restaurant,” Luedecke tells SLAM. “And I remember we had the ‘Flow Like Water’ colorway at that point.”

His colleague, Steve Segears, Senior Merchant, Global Merchandising at Curry Brand, is smiling along with the beginning of Luedecke’s story.

“Steve did a phenomenal job of just storytelling and digging into all the materials and colors, opportunities along the way,” Luedecke continues. “And [Stephen] puts on the shoes and the moment he has them on his feet, you just see, like, this smile on his face, he’s just smiling, and he goes into the corner, he bounces up and down, he does a couple of things. We’re in a restaurant, in the backroom of a restaurant, so there’s no way for him to take them out on the court, but you can see, he’s like, ‘That’s the shit right here.’”

And then both Luedecke and Segears laugh. That was the moment that they knew years of hard work were going to pay off.

The two-time MVP confirmed the story a few days later.

“No doubt,” Curry begins. “That moment was special because it allowed me to kind of see the future and where we could go with product and just that experience for anybody that wears it. For me, like you know, I always get excited for that moment when you try something new but this one was something that kind of took it over the top in terms of the feel, the comfort, obsoleting rubber, and just the whole story behind Flow. From there the excitement around what we were building was kind of cemented. Now that it’s actually on shelves and on fan’s feet all across the world, it means a lot to know that that’s where it all started.”

“I remember that meeting we had with him at Stanford,” Segears adds. “At the time, Steph still had the hand injury, so he had a big cast on his hand, and I remember we actually had to get someone to put his shoe on for him, tie it up. I remember that smile that was on his face. I think on one foot he had, I think, the Curry 7. He puts the prototype of the Curry 8 on. He just gets up, you can just see this smile, almost like this big grin, as if he just hit the game-winning three pointer just coming across. And I will tell you even though he [had] the actual cast on, it was hard getting that shoe off his foot. I think he would’ve went out wearing those shoes that day if we would’ve let him.”

“He kept the shoes,” Luedecke jumps in. “I think that’s one of the first leaks when you were on the Warriors Instagram, some of those leaks were from that specific product because that’s the one he actually was like, ‘Ahhh, I’m taking these.’”

What made that moment so special for Curry was the introduction of Flow. It’s a proprietary technological leap forward that allows for a completely rubberless outsole made of foam. It doesn’t slide, which means it doesn’t squeak. Squeaking and sliding costs time on the court that could result in open looks or in blown defensive assessments. Rubber has been a mainstay of basketball sneakers for a century and it continuously squeaks, echoing throughout every gym and park where there’s a hoop. Flow is the silent antidote.

That was the night that Curry got to finally experience a near-finished version of the all-new system.

Luedecke explains that the idea of Flow first began in 2017. A group of chemists and engineers were just talking one day, trying to imagine something big, “pie in the sky” ideas, as Luedecke puts it. Their discussion led to UA’s signature cushioning platform, HOVR, a development that marked another big moment in their design history. That foam compound was wrapped in what UA called an Energy Web. The Energy Web was a mesh fabric made to protect the foam. When the elements interacted, responsiveness and energy return was engaged.

Those brainstorming sessions to improve on HOVR continued through 2018 until a note came through from UA’s counterparts in Shanghai. A small shipment of tiny foam fragments showed what could be possible. More work followed until, eventually, Luedecke was able to use the new foam on some prototype running sneakers but didn’t have any specific high-level expectations.

His counterpart, Fred Dojan, put the protos on one morning at their office. He started running around the in-office basketball court. By the time that Luedecke clocked in to work, Dojan was adamant that he try the product as well. And Luedecke was shocked to find out how well they gripped the hardwood and how light they were.

Then their lives started moving in fast motion. They knew they wanted to have Stephen be the main driver of this new vehicle. Four prototypes with four different uppers were created. But the foam, the material that would become Flow, stayed consistent.

Those protos were taken out to Cali to show number 30. After he learned about the biometric details and got to run around in them a little bit, he shared his thoughts.

“He’s like, ‘Alright, well, I want the 8—that needs to be the 8, that needs to be the next shoe,’” Luedecke remembers.

The VP then makes a sound effect of an explosion.

Segears adds that the Flow tech was supposed to drop in 2022.

Monthly meetings with the three-time champ happened for more than a year. He had long been asking about how to make his sneakers better, from an innovation standpoint. He would ask questions throughout all their meetings, continually pushing for the most contemporary platforms and materials.

“He’s really into technology in his personal life, as well,” Segears says of Curry. “When it comes to innovation, we look at him as the guy that we want to put at the forefront of innovation. When it’s something that makes him better and he can feel it, like Flow does, we want to make sure that we’re getting all those insights. He was very hands-on throughout the process. There were a lot of late-night phone calls. Just him checking in. Like, ‘How are we doing on the process? Are we going to get this for the 8?’ And he was adamant. He was like, ‘I’m not putting anything else on my foot unless it’s that Flow technology.’”

“The way the product is built is the opposite from other basketball shoes and that’s coming from somebody who’s built a lot of basketball shoes,” Luedecke says. “Usually you try to get to stability first and then kind of whittle away a little bit to get to where it’s flexible enough to feel it on the foot. This is the opposite. We started with flexible as a point of departure. When you glue foam and rubber together, by definition, it’s like a plywood. It creates a stiff surface or something that doesn’t want to flex very well. I would say in every other basketball shoe, you’re fighting that. There’s somewhere to flex a little better or somewhere to take things out. Then you’re wondering whether it’s still going to be stable enough. That process was super interesting, even on our side. ‘I have to take every preconceived notion, everything I know about how to build a basketball shoe…’ That includes our engineers. You’ve got to think that through all the way to the factory. Even the factory guys were like, ‘That’s not how we build a shoe.’ We don’t want to mess with the flex, we don’t want to mess how soft it is, we don’t want to mess with how comfortable it feels. This wants to bend, this wants to work with your foot. That was a really, really fun exercise to go through.”

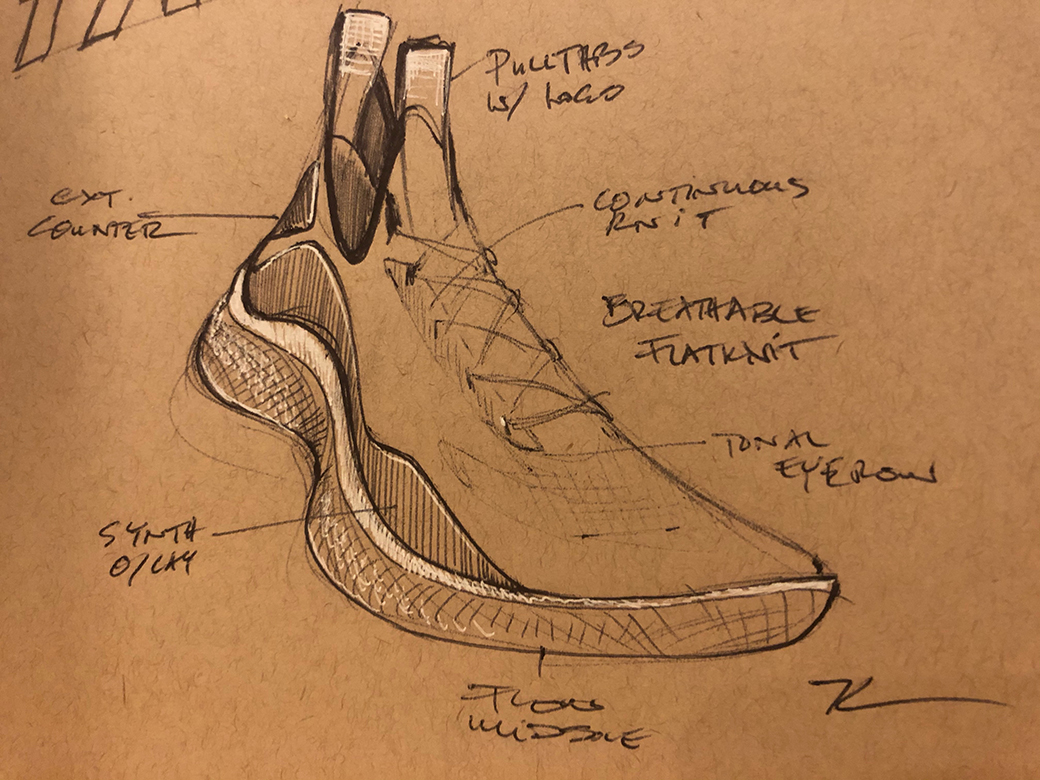

The all-foam outsole needed to complimented by an upper that was just as powerful, but not something that would overshadow the new tech. They went with a knit that features synthetic overlays where the foot is vulnerable. Luedecke brings up the bi-directional internal fit structure that was included in the 8.

“There’s two directions of support that are independent of each other. They’re not laminated. Depending on if you stop, or if you cut, there are different elements that come into tension,” he says.

The external heel counter and the internal heel bootie finish off the 8’s tech specs. But the silhouette is really all about Flow.

“It’s something,” Curry said after the launch of Flow, “you ain’t never seen before.”